Quality forged by experience

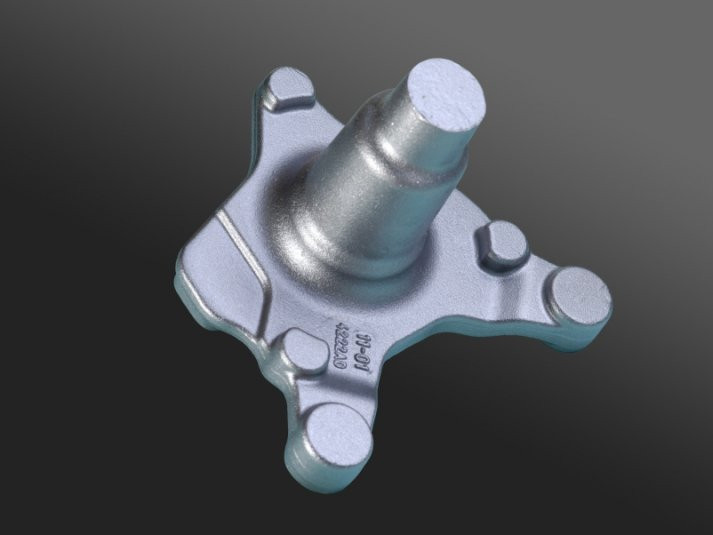

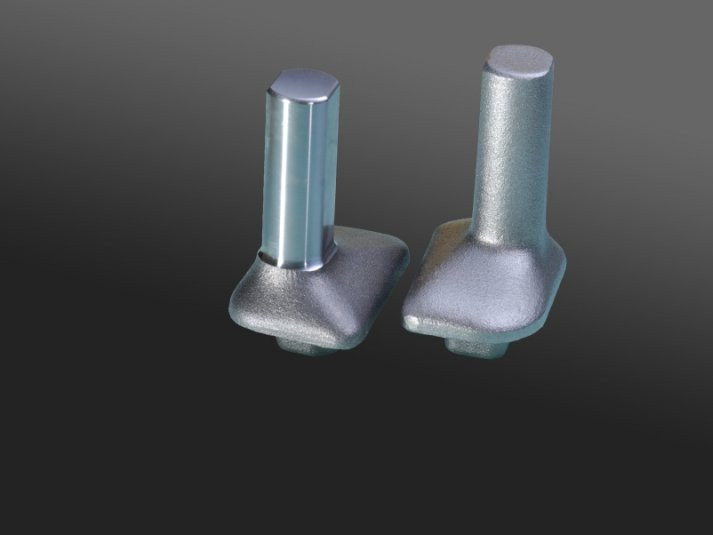

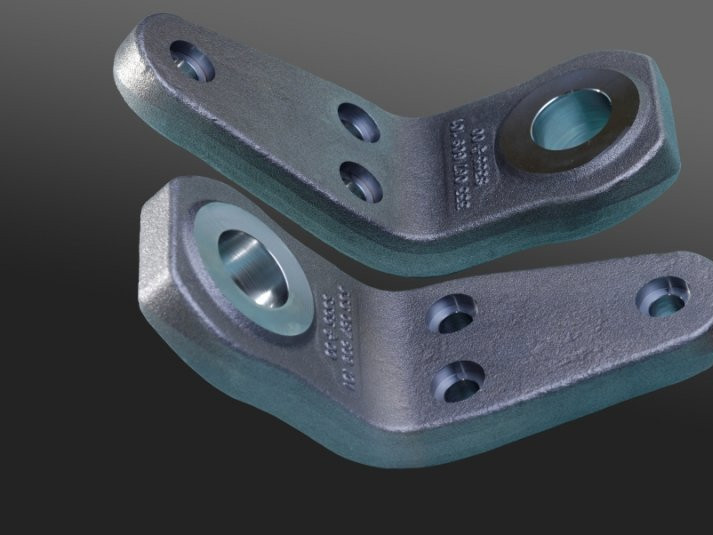

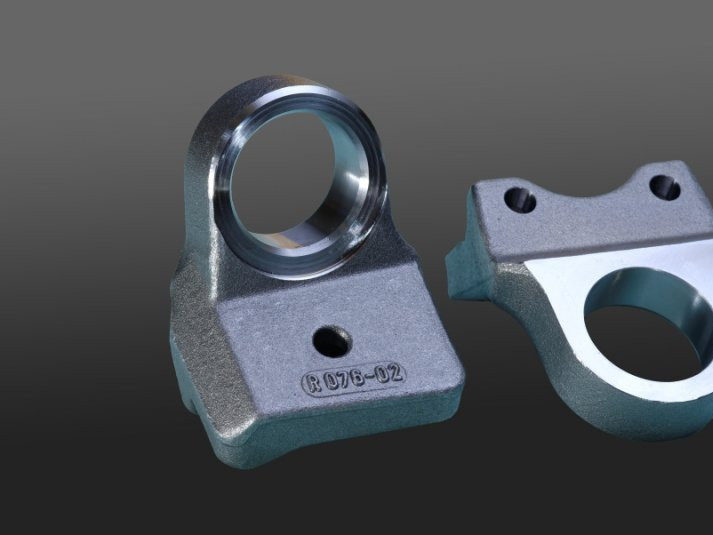

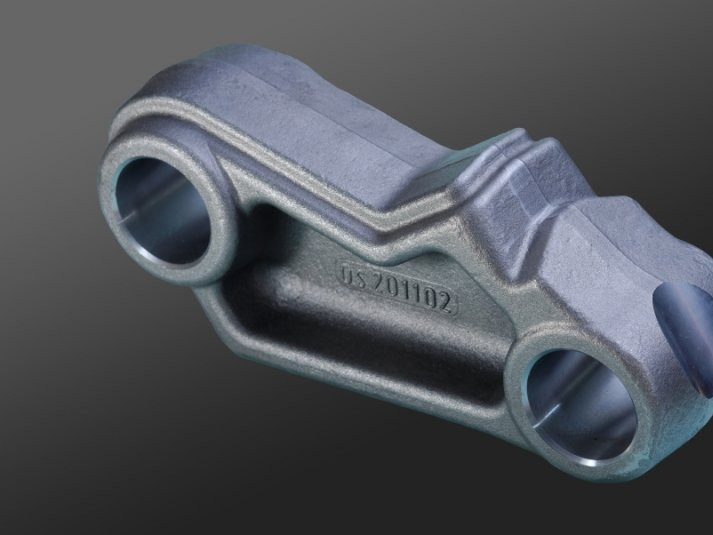

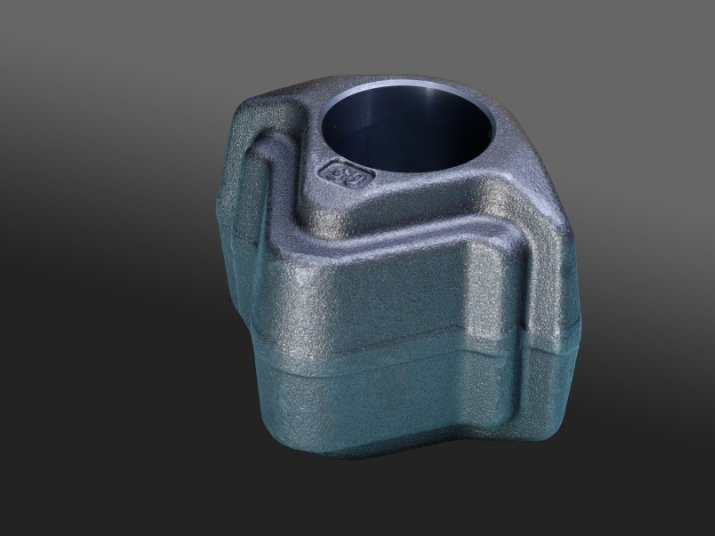

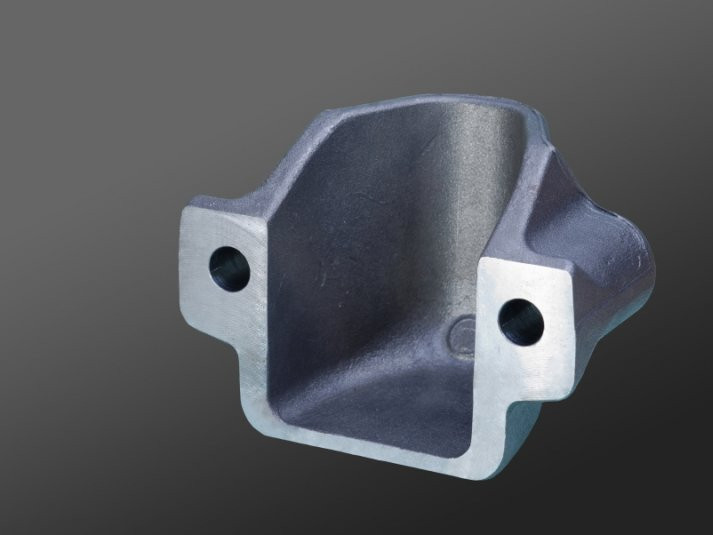

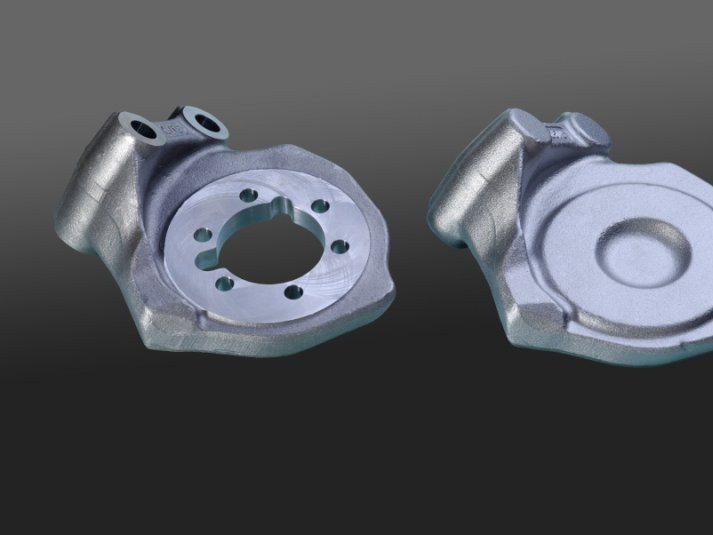

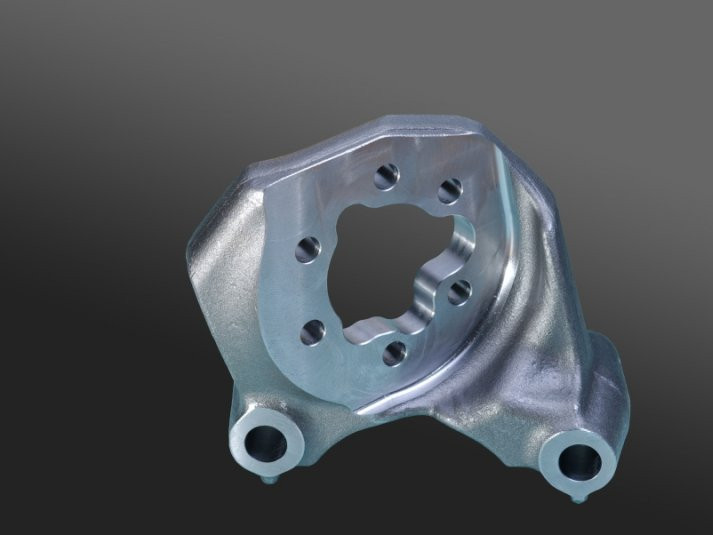

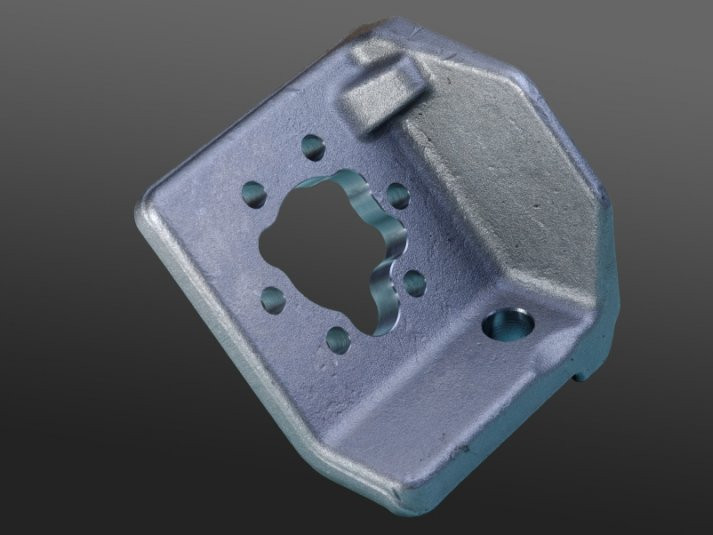

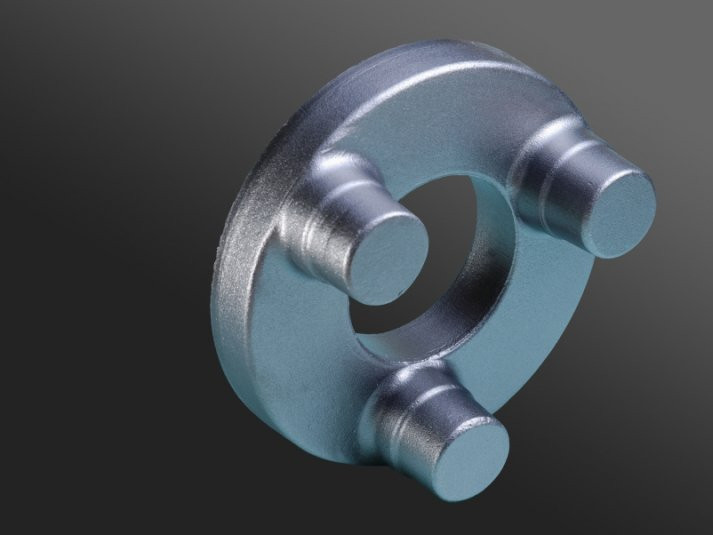

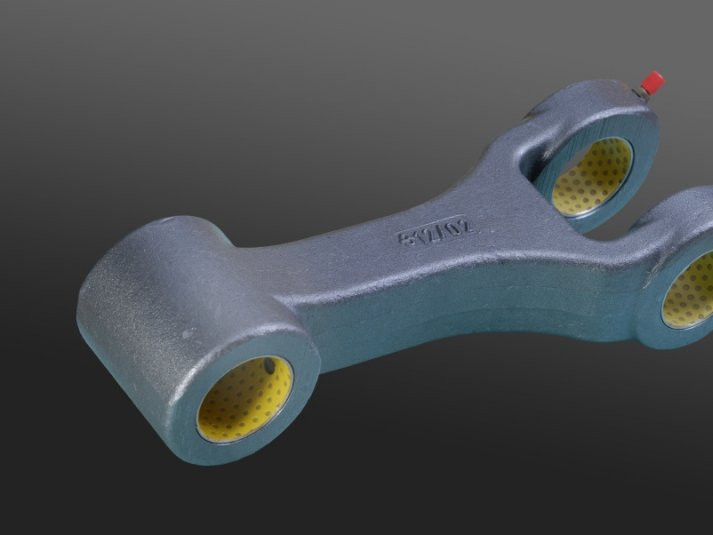

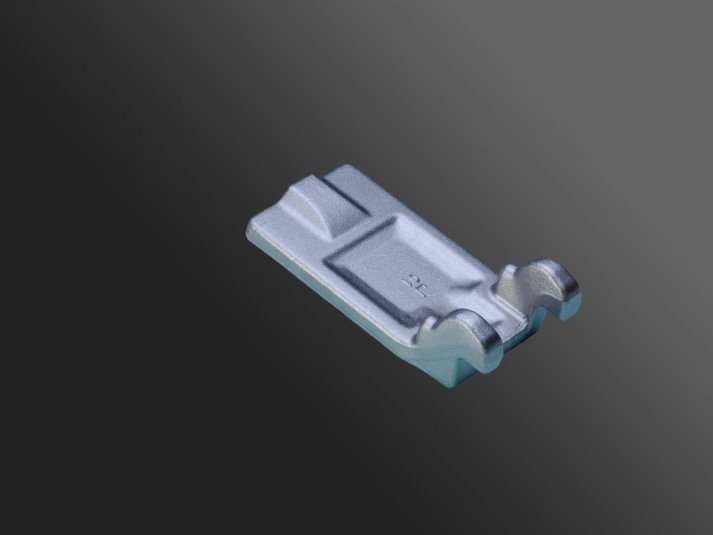

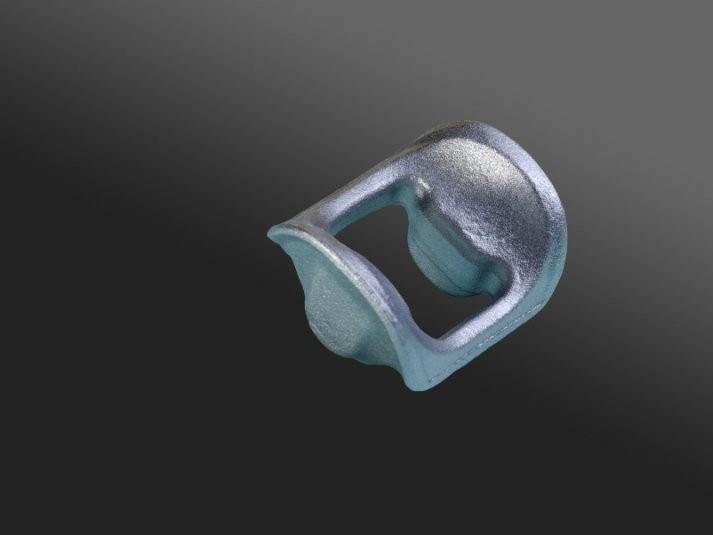

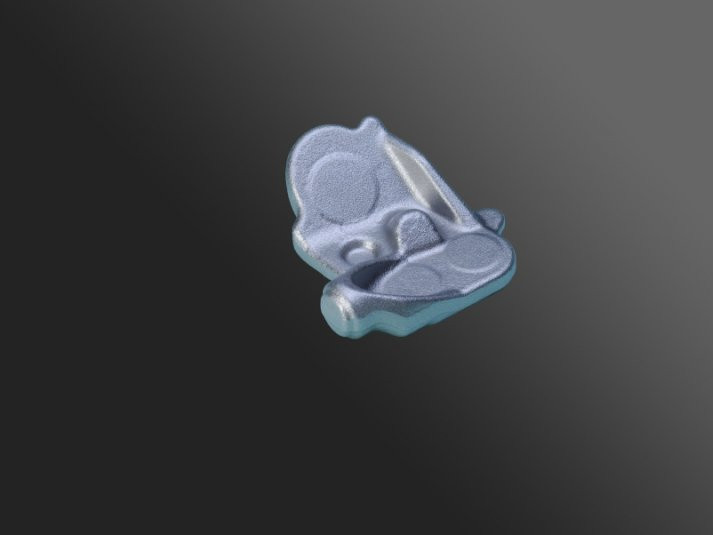

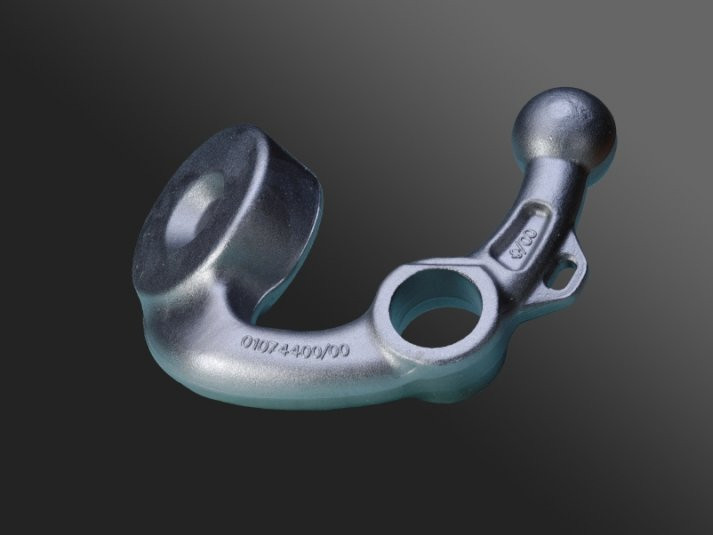

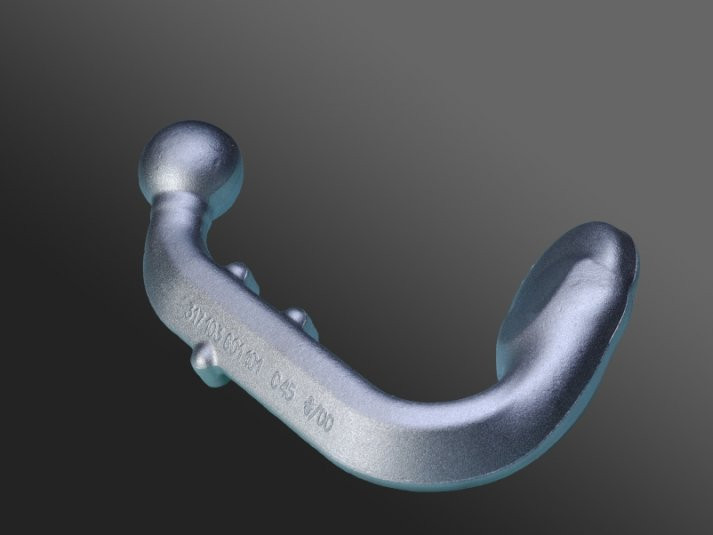

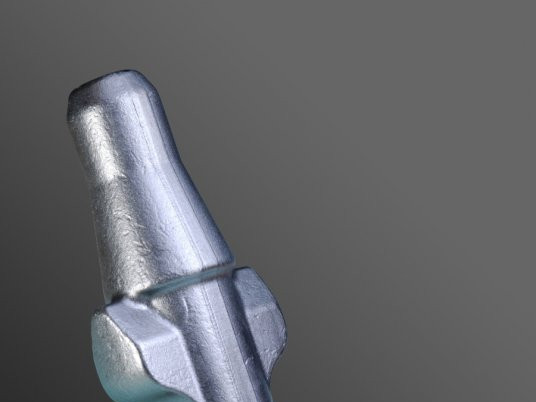

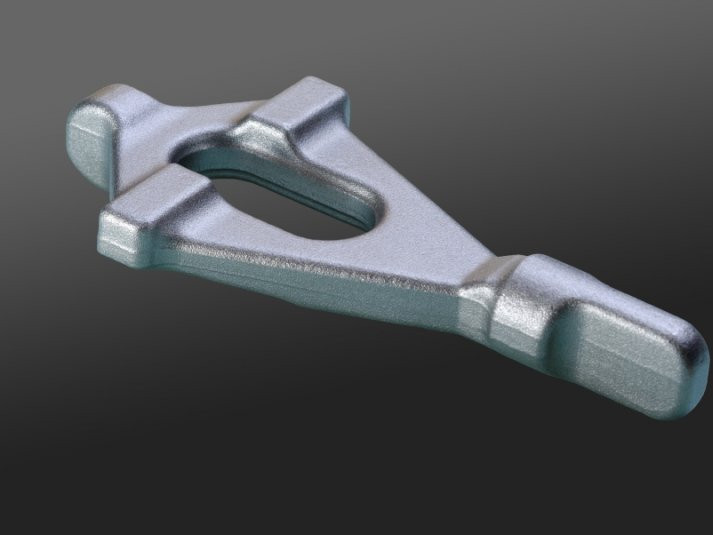

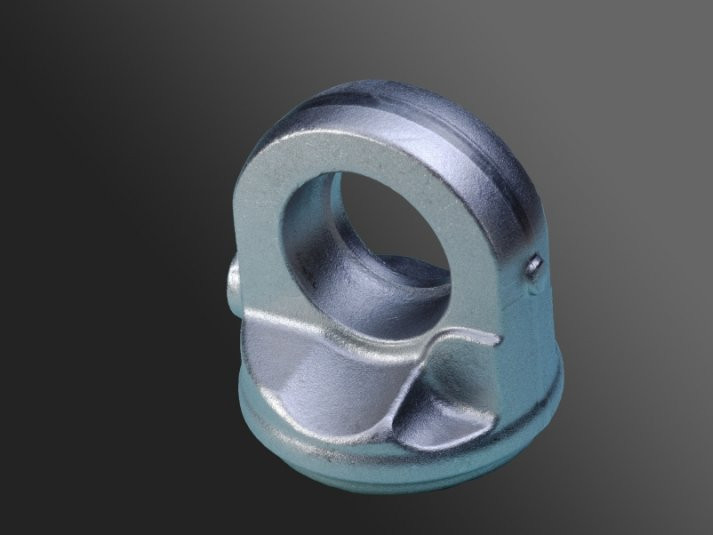

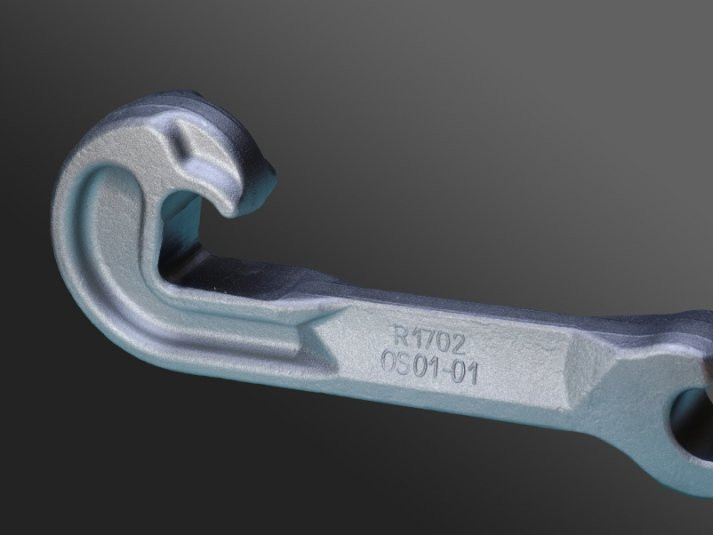

Steel die forgings are essential in the automotive industry, logistics, agriculture, and general engineering, where high durability and stress resistance are required. At OSTROJ, we combine cutting-edge forging technologies with rigorous quality control to produce components that meet the strictest customer and industry standards. Our forgings are integral to the chassis and accessories of leading global vehicle brands, with a significant portion dedicated to safety-critical and specialized parts.

We specialize in complex-shaped forgings with intricate parting lines, typically weighing between 0.5 and 20 kg. Our comprehensive manufacturing process includes:

- Steel bar cutting,

- forging & heat treatment,

- shot blasting & finishing,

- calibration & 100% surface defect inspection,

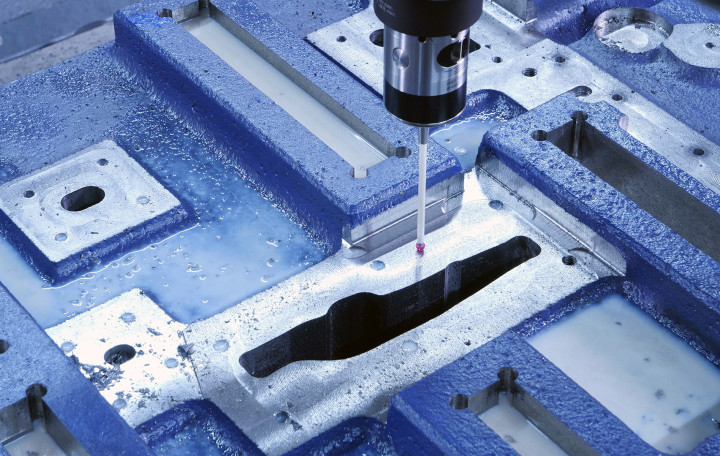

- precision CNC machining,

- electroplating, painting & final shipment.

By handling the entire production process under one roof, we ensure uncompromising quality, efficiency, and reliability.